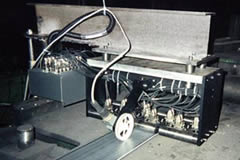

Olympus Plates In-line Inspection System

Olympus Updated: 2007-09-11Our eddy current array inspection system advantageously replaces liquid penetrant in the inspection of flat surfaces, producing results much faster and without any chemical handling. Furthermore, results are stored on standard PC-based hardware and can be transferred in customized reports.

Also, array probes are a great alternative to the long dead zone, low sensitivity, and high maintenance level of the standard flat, rotating probe heads. Eddy current array probes are sized to cover a wide surface to lower the number of passes and, since there is no need for moving mechanical parts, the probes have a very high longevity and require little maintenance.

The system performs inspections of magnetic and nonmagnetic materials for detection of surfacebreaking and near-subsurface defects. The probe configuration detects axial and transverse defects. Plates of varying widths can be accommodated by simply adding or removing probe modules. Online production testing can reach speeds of up to 1m/s.

Added benefits include: no need for contact fluid and the ability to inspect beyond the first layer of a multilayer structure.

There are no manuals currently available for this model.

Related Manuals

Olympus ERW Tube In-line Inspection System

Olympus 5800PR/5900PR/5627RPP-1 Pulser-Receiver

Olympus Wire/Rod/Bars In-line Inspection System

Olympus 5072PR/5073PR/5077PR Manually Controlled Pulser-Receiver

Olympus QuickScan EC In-line Inspection System

Olympus 5058PR High Voltage Pulser-Receiver

Olympus Ultrasonic Preamplifiers Pulser-Receiver

Olympus QuickScan UT In-line Inspection System

Olympus Wing Industrial Scanner

Olympus PowerStation In-line Inspection System

Olympus Glider Industrial Scanner

Olympus µTomoscan Portable Ultrasound Inspection System